Adhesive Vinyl

Pressure Sensitive Vinyl – Calendered

• Calendered vinyl-3 mil

• 4-year calendered PVC film

• Short to medium term outdoor applications

• Solvent printable white permanent adhesive

Vinyl Characteristics:

• 3-mil, soft-calendered PVC film available in white with a gloss or matte surface

• Pressure-sensitive adhesive that sticks where you want it, for as long as you need it, without cracking or peeling

• Typically used to reduce glare

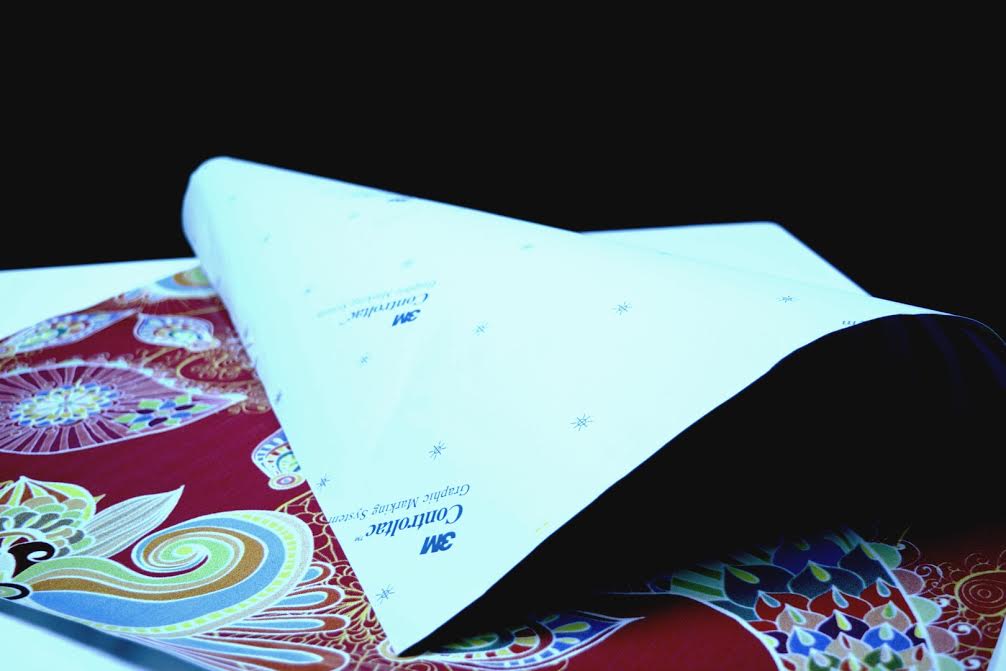

3M ControlTac Spec.

Pressure Sensitive Vinyl Semi-Gloss

Vinyl Characteristics:

• Without adhesive: 2 mil (0.05 mm)

• With adhesive: 3-4 mil (0.08-0.10 mm)

• The adhesive technologies in this film offer pressure activation, slideability and repositionability for fast and easy, bubble-free applications.

• Use it long-term durable for signs and fleet graphics even on corrugated and riveted surfaces. This product is a durable film with superior conformability.

• Whether you are promoting a short term advertising campaign or need it for long-term applications 3M Cast is the ultimate choice.

Weathering:

Weathering-Stands up to a range of tough environmental conditions including UV rays, moisture, temperature extremes [-59℉ to +192℉ (-50℃ to +90℃)] and abrasion.

Recommended Application Surfaces:

Stainless steel, aluminum, glass, ABS, polycarbonate, Plexiglas® automobile enamel and standard mounting boards like Sintra®, Gatorfoam® and Fome-Cor®. The product is designed for use on smooth, flat surfaces and should not be applied over corrugations or rivets. Textured surfaces and wood tend to promote poor adhesion. Always pretest your specific substrate prior to actual application.

Surface Preparation:

Always ensure that the receiving substrate is thoroughly cleaned, free of dust, dirt or cleaner residues. Walls primed with latex paint should contain no waxes or silicones. Metal and glass surfaces can be cleaned with standard glass cleaners. Poor surface conditions will cause adhesion loss or failure.

Installation Techniques:

Proper contact of the adhesive to the mounting substrate is critical, and maximum pressure should be used to install the vinyl. If insufficient pressure is used during the install, the edges of the vinyl can lift. When applying vinyl to mounting boards, it is recommended that a cold roll laminator be used to give adequate, even pressure during application. For installations by hand, use application tape and squeegee with adequate pressure. It is recommended that water not be used during the installation, but if it is used, use minimal amounts. All water must be squeegeed out from under vinyl. If liquid soap is added to the water to increase the ease of installation, use only one drop per gallon of water. Soap must not contain moisturizer. Do not use heat guns to install vinyl. Material should not be stretched during installation. It is a calendered vinyl, and it will shrink back to original size, which might cause edges to lift or create gaps between panels.

Removal:

The adhesive is very aggressive and removal may cause damage to indoor painted surfaces or drywall surface. To increase the ease of removal, gently heat the vinyl with a heat gun to soften the vinyl and adhesive. The longer PSV is mounted, the more difficult the removal will be. Different surfaces will have different adhesion characteristics. Glass and stainless steel usually promote extremely high adhesion values and removal may be more difficult than with other surfaces. If during the removal adhesive transfer happens, soapy warm water and aggressive rubbing with a cloth should remove adhesive. For surfaces with more difficult adhesive removal, isopropyl alcohol (a.k.a.- IPA or rubbing alcohol) can be used.

3M ControlTac Spec.

Depending on how large your PSV project is, your product could be sent in sections to help with installation.